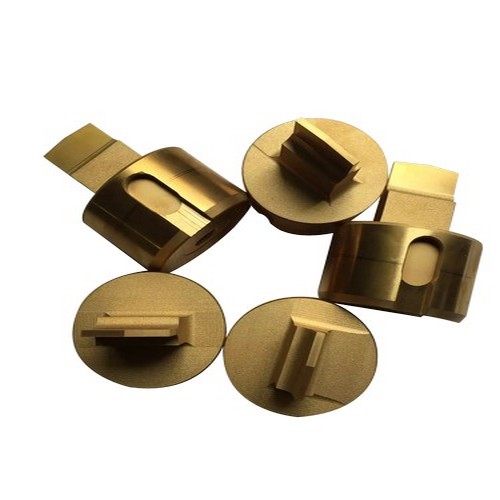

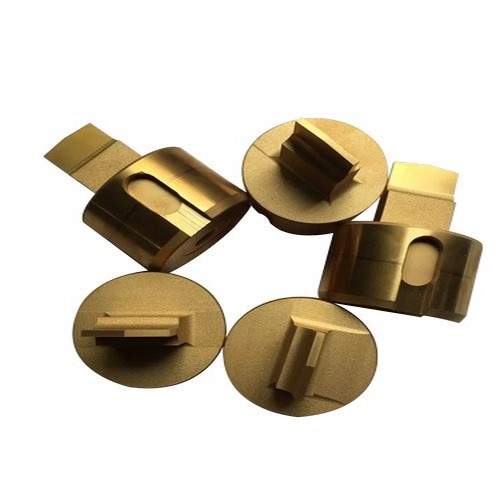

Punch press tools

Ultra structure punch body

- Part Name: Ultra structure punch body

- Material:

- Surface finish -Ra:

- Tolerance:

- Applications:

For punch body, we produce it with SKH-51. It has another name of high speed steel. This is an alloy steel with complex composition. It includes tungsten, molybdenum, chromium, vanadium, cobalt and other carbide forming elements. The total amount of alloying element arrive to 10%-25%. On the condition of hot heat (around 500℃) that emerging with high-speed punching, it will keep high hardness and HRC can arrive above 60. This is also the main feature of high speed steel which is called red hardness.

This material can make the toolings more durable and wear-ressistant which will cause a longer tooling life.

The die material we choose is Japanese imported special steel DC53, which is a new type tooling steel improved from SKD11. This material overcome the weakness of SKD11’s insufficient tempering hardness and toughness. The strength and hardness is excellent while doing heat treatment, HRC can arrive to 62-63.

DC53 steel’s toughness in cold die steel is more prominent. Tools made by DC53 will have little cracks and cracking which will greatly improve the tooling life.

FOR PUNCH BODY: SKH-51

FOR DIE: DC53