Trumpf Toolings

Letter forming tool

- Part Name: Letter forming tool

- Material: punch body:SKH-51 punch die:DC53

- Surface finish -Ra: 0.0001

- Tolerance: 0.01

- Applications: Sheet mental areas

TR010501-forming tools series

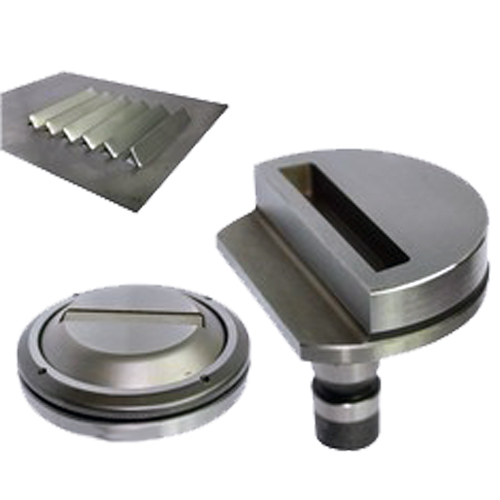

Closed Louver Tool

1.Different plate thickness corresponds with different mould;

2. While using, please pay attension on the plate moving direction and set asside engough discharging time.

3. Non-molding pitch (A) should be larger than 3 times plate thickness.

4. Forming height: 3-4 times steel plate thickness, 2-3 times alum plate thickness, 1-2 times staniness steel plate thickness.

5. The higher the forming size, the serious the pull phenomenon.

6. For plate thickness less than 1.2mm, R should be larger than 10mm so as to avoid corner tearing.

Nibbling Louver Tool

1. Steel plate and alum plate thickness is 3.0mm

2. Stainless steel plate thickness is 2.5mm

3. Using min. nibbling pitches

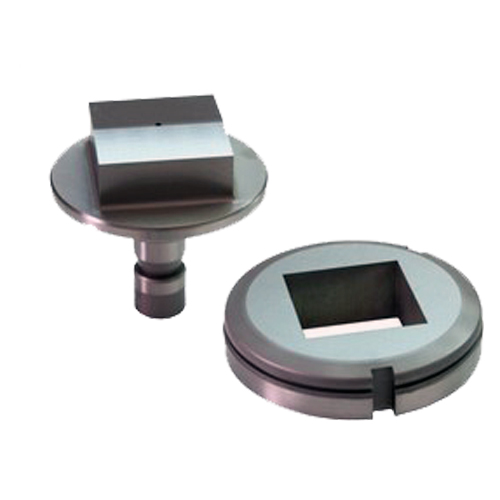

PierceEmboss Tool

1. Reasonable angle and fillet to confirm a better shaping.

2. Special height, angle and fillet will increase material stress.

3. The higher and deeper molding requires to smoothen material or lubricate plate while processing.

4. The reasonalbe angle is 90 degree.

5. The optical forming height is within 3 times plate thickness.

6. Must ensureΦD>5T+Φd so as to prevent die intensity weak when punching hole.

Cluster Tool

1. Changable punch inserts, low cost.

2. Must avoid one hole repeat punching.

3. Too small pace will damage the die while processing. The suggested pace should be larger than aperture.

4. To confirm the die strength, the distance between hole should not be smaller than 3.2mm, or larger than 2 times plate thickness.

5. Cluster tool has integral and inserts structures, we can design mold structure according customer’s requirements.

6. Generally, customer only need to buy punch assembly, die and stripper plate (PDS).

Rib rolling tool

1. CNC punch press must has relative operation system and control program.

2. Can process curve, arc and round. The upper and lower roller in the die make with coating process and can be changed seperately.

3. Different plate thickness need different tool. Customer only need to order upper and lower roller so that to save money.

4. High-speed molding is equal to the fast moving speed of X and Y aix on the machine worktable.

5. The min. turning radius is R40mm, the turing radius has no relation ship with forming width.

6. Process range: stainess steel thickness is 0.8-1.5mm ; carbon steel plate thickness is 0.8-2.0mm; alum plate thickiness is 0.8-2.5mm;

Forming height: 2-3 times of plate thickness, width is 2 times height, max width is 12.7mm.

Threaded hole extrusion tool

1. Before flanging, need to pre-punch hole.

2. Need to reserve unloading time when setting process program and flanging part has a little tilt.

3. Extrusion tool corresponds with plate thickness, different plate thickness requires different tool.

4. Max process plate thickness: steel plate and alum plate is 2.3mm; stainless steel plate is 1.2mm; Forming height: H>=2T.

5. We can design the extrustion punch press tool according to customer’s requirements. But the forming shape is not as good as pre-punch hole first and then do flanging.

Bridge Forming Tool

1. Bridge width should be larger than 1.5 times plate thickness and bridge width should be larger than 1.8mm.

2. Program shoul reserve enough unloading time while using.

3. Tool is corresponding with plate thickness. Different plate thickness requires different tool.

4. We can desin single bridge, double bridge according to the min.distance between brdigh hole, and the forming top is flat surface.

5. If you need curved top surface on the forming top, please notice us in advance with written explaination.

6. Due to different plate plastic property, the forming height of the steel and alum plate should be 1.5 times plate thickness, and for stainless steel, the forming height is 2 times plate thickness.

7. For enlonged shape and thin plate, the bridge top will be a little concave after forming.

8. To coordinate with trumpf machine’s high-speed blanking, the lower die designed with rolling guide which will not scratch the plate.

Trumpf Multi 10 Letter Forming Tool

1. Can be used with trumpf MT10 tool, so that to print 0-9 figures freely by different combination.

2. Can realize product’s marking work conveninently and quickly, which will also prevent material confusion and improve work efficiency.

Emboss Tool

1. The reasonable angle is 90 degree, a suitable fillet can make a better molding result.

2. The best forming height is less than 3 times plate thickness.

3. For higher and deeper forming: require smooth material or lubricate plate while processing.

When using, program need to reserve enough unloading time.